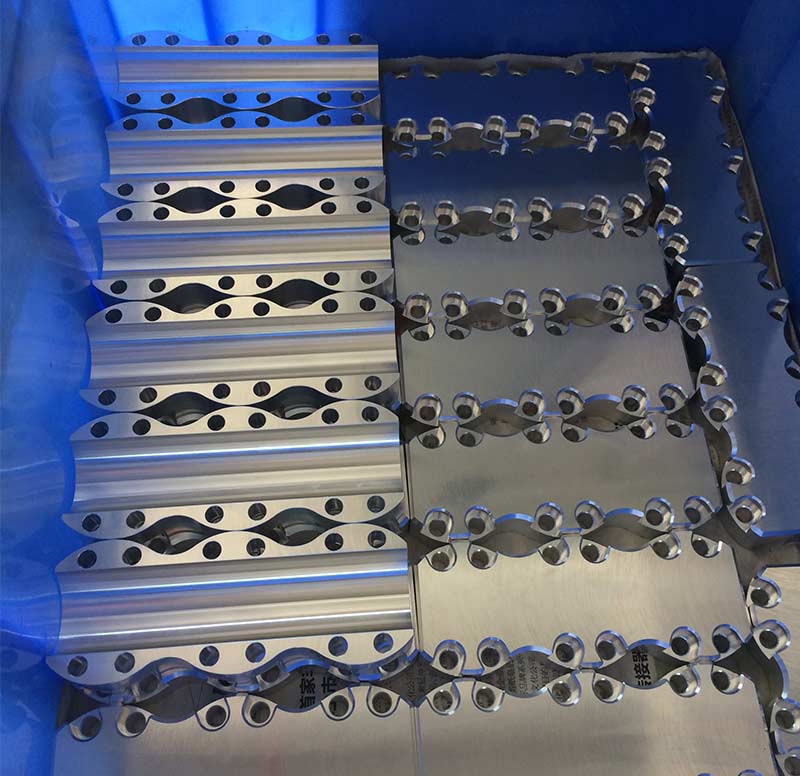

First will be the geometry information and technology of the CNC machining parts on the drawing information digitization, relative motion trajectory of the cutting tool and the workpiece, CNC machining such as the Precision Aluminum Parts Processing ,spindle speed and feed speed in the process of transformation, the switch of cooling fluid, the workpiece and cutting tool transformation control and operation, all in accordance with the provisions of the code and format into processing procedure, and then input the program into CNC system.

CNC system is in accordance with the requirements of the program, first the corresponding operation, processing, and then issued a control command, so that the coordinate axis, spindle and auxiliary action coordination, to achieve the relative movement of the tool and the workpiece, automatically complete parts processing.

CNC machine tool precision selection to consider the following factors:

CNC machine tool precision and machining process precision is not the same, they represent the CNC machine tool is different two concepts, one is the machine tool's own precision and the other is the process of its machining precision. The two reasons do not seem to be related, but they are related.

It is wrong to mistake the position accuracy on the Aluminum Alloy Mechanical Parts Customization Manufacturer's sample or on the product qualification certificate for the machining accuracy of the machine tool. The position accuracy indicated on the sample or certificate is the accuracy of the machine tool itself, and the machining accuracy is the sum of errors generated by various factors in the whole process system including the allowable errors of the machine tool itself. In the selection, the process capacity of KP evaluation method can be referred to as the basis of precision selection.

Nc precision has a decisive influence on machining quality. It should be noted that machining precision and machine tool precision are two different concepts. The rigidity of machine tool directly affects the productivity and machining accuracy. The machining speed of the machining center is much higher than that of the common machine tool, and the motor power is also higher than that of the common machine tool of the same specification. Therefore, the rigidity of its structural design is also much higher than that of the common machine tool. When ordering, the maximum allowable torque, power, axial force and feed force can be calculated according to the value provided by the manufacturer.