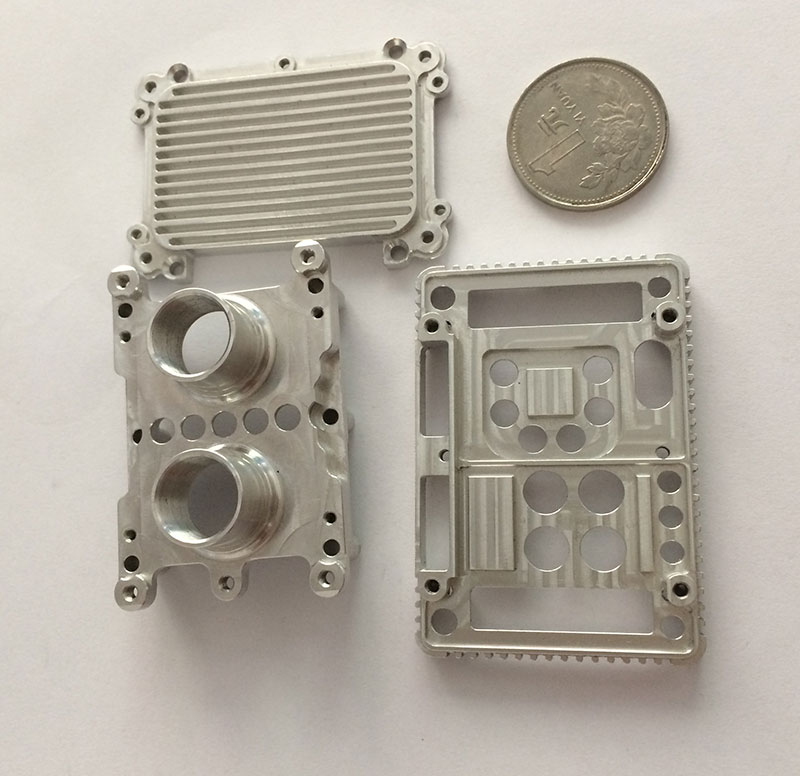

What factors should be Precision Aluminum Parts Manufacturer considered in choosing the surface machining method of CNC machining workpiece:

1. The machining accuracy and surface roughness obtained by any CNC machining method have a considerable range, but only in a narrow range is economic, and the machining accuracy of this range is the economic machining accuracy. Therefore, when selecting the processing method, the corresponding processing method that can obtain the economical processing precision should be selected.

2, to consider the nature of CNC machining materials.

3. The structural shape and size of CNC machining parts should be considered.

Consider productivity and economic requirements. Advanced technology with high efficiency should be adopted in mass production. It can even fundamentally change the manufacturing method of the blank and reduce the amount of labor for machining.

5. The existing equipment and technical conditions of the factory or workshop shall be taken into consideration. When selecting processing methods, the existing equipment shall be fully utilized to tap the potential of the enterprise and give play to the initiative and creativity of the workers. However, consideration should also be given to the continuous improvement of existing processing methods and equipment, the adoption of new technologies and the improvement of technological level.

The above is the selection of CNC machining surface machining method to consider what factors, Custom Aluminum Parts CNC machining surface machining method depends on the technical requirements of the surface. The selected CNC machining method should meet the requirements of part quality, good machining economy and high production efficiency.