For CNC machining, as long as the CNC machining equipment (CNC machining machine) reputation do well, the price is reasonable, CNC machining in the industrial market has a leading edge, but they often ignore the most important CNC CNC machining machine operation and maintenance. So how to maintain CNC machining CNC machine tool? Jingzhixing CNC customized parts Exporter here to introduce to you.

CNC machining CNC machine preventive maintenance is the key to strengthen the daily maintenance, the main maintenance work has the following contents: daily inspection, weekly inspection, monthly inspection, quarterly inspection, semi-annual inspection. The preventive maintenance of CNC machine tools is as follows:

1. Daily inspection of CNC machine tools

Its main projects include hydraulic system, spindle lubrication system, guide lubrication system, cooling system, pneumatic system. Daily inspection is based on the normal condition of each system to test. For example, when the process test of spindle lubrication system is carried out, the power lamp should be on and the oil pressure pump should operate normally. If the power lamp is not on, the spindle should be stopped and the mechanical engineer should be contacted. Maintenance.

2. Weekly inspection of CNC machine tools

Its main items include machine tool parts, spindle lubrication system, should be a weekly correct inspection, especially for machine tool parts to remove iron debris, external debris cleaning.

3. Monthly inspection of CNC machine tools

The main power and air in the dryer to check. The power supply voltage is rated at 180v-220v under normal conditions, and the frequency is 50Hz. If there is any abnormality, it shall be measured and adjusted. The air dryer should be removed once a month and then cleaned and assembled.

4. Quarterly inspection of CNC machine tools

Quarterly inspection should be mainly from the machine bed, hydraulic system, spindle lubrication system three aspects of inspection. For example, the machine tool bed inspection, mainly see the accuracy of the machine tool, machine tool level in accordance with the requirements of the manual, if there is a problem, should immediately contact the mechanical engineer. When inspecting the hydraulic system and the spindle lubrication system, if there is any problem, please replace the new oil 6oL and 20L respectively and clean them.

5. Semi-annual inspection of CNC machine tools

After half a year, the machine tool hydraulic system, spindle lubrication system and X axis should be checked, if there is a problem, should be replaced with new oil, and then clean the work. After fully understanding and mastering the knowledge of preventive maintenance, it is necessary to have a deeper understanding and necessary mastery of the cause and treatment of abnormal phenomena in the oil pressure system. Such as when the pump does not spray oil, pressure is not normal, noise and other phenomena, should know what the main reasons are, what is the corresponding solution.

The above content is the introduction of how to maintain CNC machining CNC machine tools, CNC equipment correct operation and maintenance can prevent abnormal wear of the machine tool, to avoid sudden failure of the machine tool. Careful maintenance of the machine tool, can maintain the long-term stability of the machining accuracy of the machine tool, extend the service life of the machine tool.

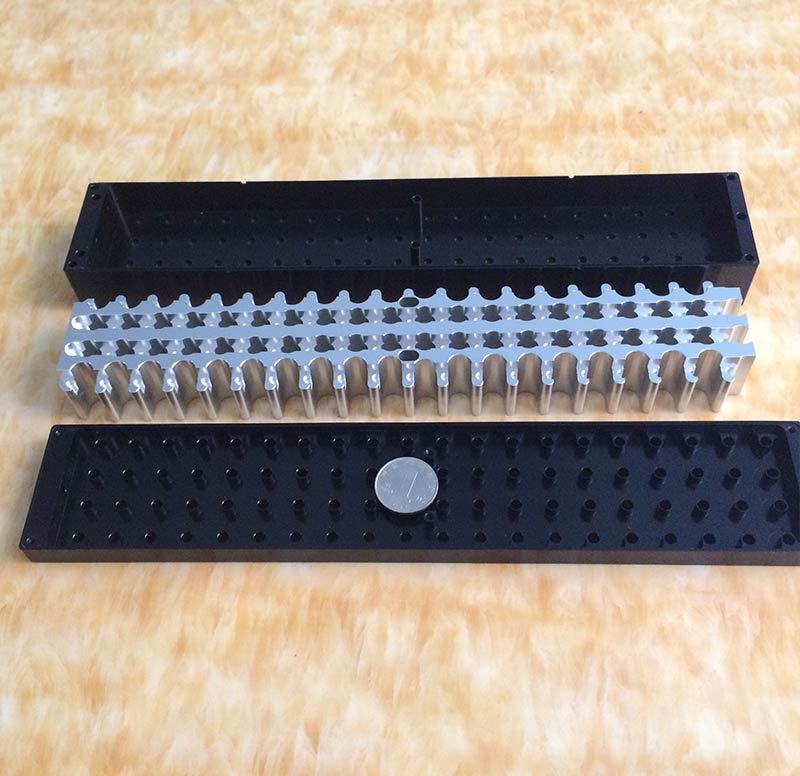

Welcome to purchase our CNC machining Aluminum alloy parts!